Long before the Isle of Harris Distillery came into being, our island was known for another product of real provenance, made by skilled local men and women and full of care, craft, and creativity.

The iconic cloth known as Harris Tweed® has been part of our community’s story for well over a century and played an integral role in the lives of generations of Outer Hebrideans.

Over the last few years, we’ve been proud to explore the rich heritage and history surrounding the warp and weft of the weaving world in our ongoing Harris Tweed Project.

We’re even more pleased to share the result of all this work with you, with the release of two new creations made from an exceptional piece of our own Clò Mor (Gaelic for Big Cloth).

The jackets, designed by award-winning Scottish designer Judy R Clark, beautifully showcase the timelessness of this famous textile through stylish cuts and depth of colour.

Little has changed in the way the cloth has been made over many decades. Every strand of yarn used is still made from pure new wool, dyed and spun here in the Outer Hebrides.

From a careful palette choice, picked from a myriad of colourful hues, the wool is roughly blended, carded, and then spun, every part of the process taking place here in the islands.

These fragile threads are then handwoven by local weavers at their homes using manual looms into patterns of plain twills, herringbones, and plaids of all kinds.

Exactly when tweed was first made here is lost to the winds of time, but we know that the early wooden looms used the shin bones of sheep as rudimentary shuttles.

Lichen, like ‘crotal’, was scraped from rocks and boiled to create a natural dye for the freshly shorn wool, and spinning would have been done by hand using simple stone spindle whorls.

This basic cloth would have been heavy and hard-wearing and only used domestically at home, or perhaps bartered for other useful goods within the community.

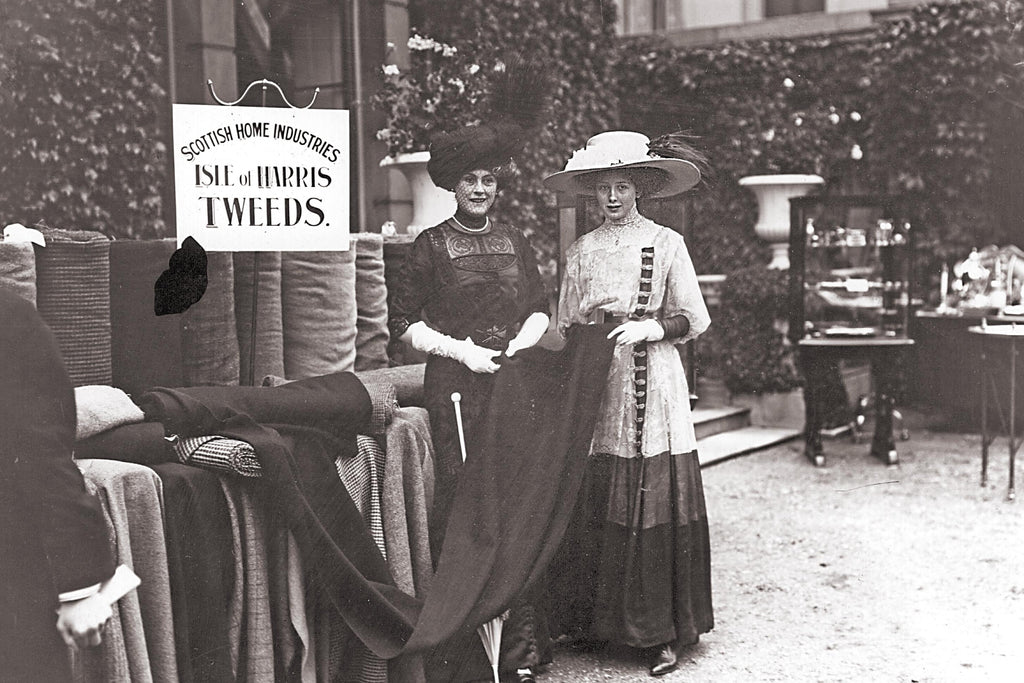

It wasn’t until 1846, Lady Dunmore, widow of the landowner of Harris, had her clan tartan replicated by Harris weavers in tweed that things took off commercially.

So pleased with the results, she began to devote much time and effort to marketing the tweed to her wealthy friends further afield, and it quickly gained a reputation among the private estate sporting set.

The rest, as they say, is history. Over the course of the 20th century, Harris Tweed has enjoyed and endured many highs and lows as fashion trends and favourite fabrics came and went.

From the stars of the silver screen to the catwalks of Paris and Milan, our local cloth has been much loved and lauded by the great and the good. It’s safe to say some things never go out of style.

Today, our distillery cloth remains true to over a hundred years of tradition and meets every demand made by the Harris Tweed Act of 1993 to ensure complete authenticity.

To learn more about the long history behind the clo mor, please visit the Harris Tweed Authority website and our project page to discover the first releases in our Distillery Harris Tweed range.

|